When preparing to make an instrument,

one must first of all consider one's choice of materials

and create a strategy of design. The rough flitches of

wood used for the front and back plates are glued

together with joints that must last perhaps for hundreds

of years. To shape the outline of the thin strips of maple called the

ribs, a mould is made which is later removed from the

structure. The front and back plates must be worked fairly thin to be able to

resonate easily, but because they must also support a lot of tension, they are

shaped into a very exact arching. The edges of the thin

plates are then reinforced by the inlaying of the purfling

which also serves the purpose of adding a visual effect. Once the outside arching

of the plates has been shaped, the hollowing of the inside

can begin. The graduation of the plates to the proper thickness along with the

cutting of the sound holes and fitting and glueing the bassbar

are really the most difficult aspects of violin making. No two pieces of wood

have the same properties and must therefore be worked differently every time.

The carving of a scroll on the end of the neck of as stringed

instrument has a long tradition and probably has symbolic archetypal significance.

After the finished instrument has been coated in a glorious veil of tinted varnish,

it can be adjusted tonally by means of the sound post

and other aspects of the final fitting up.

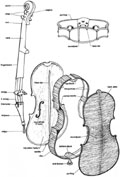

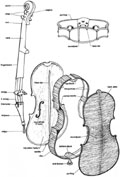

violin exploded view

Here are some very useful measurements of violin family instruments.

Please let me know if you come across any mistakes or have suggestions on adding

to or improving this list.

The Violin, The

Viola, The Cello and The

Bass

MATERIALS

The

woods traditionally employed for the construction of the violin family instruments

are maple or sycamore

for the back, ribs and neck, and generally spruce for the belly. The variety

of maple used most generally is the Acer Pseudoplatanus and Acer Platanoides.

The maples are medium sized trees with long-stalked, palmately lobed leaves,

small regular flowers and a characteristic winged fruit called a "samara" or

key, borne in pairs.

The

woods traditionally employed for the construction of the violin family instruments

are maple or sycamore

for the back, ribs and neck, and generally spruce for the belly. The variety

of maple used most generally is the Acer Pseudoplatanus and Acer Platanoides.

The maples are medium sized trees with long-stalked, palmately lobed leaves,

small regular flowers and a characteristic winged fruit called a "samara" or

key, borne in pairs.  The spruce used most often for stringed instrument fronts is the Picea

abies or the Picea excelsa, the common christmas tree, with its whorled

branches, narrow needlelike leaves which are borne on short peg like projections

of the stem. It is sometimes said that wood suitable for violins is that which

has grown at high altitudes and has had to suffer harsh conditions such as cold

weather and poor soil. While this might seem slightly myth oriented, it is nonetheless

true that wood which has grown too quickly in lush environments and rich soil,

generally tends to be less resonant and less able to withstand the stresses

it is subjected to in the finished state. It is also a well known fact that

air dried wood, seasoned for some years, without being kiln-dryed is far better

choice. This is especially true for musical instruments which are shaped to

a thin form and must bear the considerable tensions of the taut strings. Normally

8-10 years are considered necessary to season quality tone wood. If fresh wood

is used it will invariably distort, check and split. The violin maker bites

on his wood to try to tell whether it will be strong enough. He lets it fall

and listens for its ring. He will try to go by "feel."

The spruce used most often for stringed instrument fronts is the Picea

abies or the Picea excelsa, the common christmas tree, with its whorled

branches, narrow needlelike leaves which are borne on short peg like projections

of the stem. It is sometimes said that wood suitable for violins is that which

has grown at high altitudes and has had to suffer harsh conditions such as cold

weather and poor soil. While this might seem slightly myth oriented, it is nonetheless

true that wood which has grown too quickly in lush environments and rich soil,

generally tends to be less resonant and less able to withstand the stresses

it is subjected to in the finished state. It is also a well known fact that

air dried wood, seasoned for some years, without being kiln-dryed is far better

choice. This is especially true for musical instruments which are shaped to

a thin form and must bear the considerable tensions of the taut strings. Normally

8-10 years are considered necessary to season quality tone wood. If fresh wood

is used it will invariably distort, check and split. The violin maker bites

on his wood to try to tell whether it will be strong enough. He lets it fall

and listens for its ring. He will try to go by "feel."

One of the benefits of felling a tree by yourself is the knowledge

gained by going through the process of initially cutting and eventually seasoning

the material. In fact violin making has fortunately conserved the idea through

the centuries up until the present that thorough knowledge of the whole process

from the rudimentary steps including the preparation of all materials is the

key to a successful "feel" for the work as a whole. Even if you don't plan to

fell trees from scratch always it is certainly a valuable experience to do it

at least once or twice. Very important is to debark the wood as soon as possible

to prevent insect and fungus growth between the bark and the cambrium. A treatment

of the wood with borax solution is said to deter fungus which can cause staining

and discoloration in the wood. I have been told that an initial storing of the

trunk upright in the direction that the tree grew for some weeks is beneficial

(possibly to do with settlement of sap that is still trapped in the pores. Storing

the wood for the first few months is generally done outside under a simple shelter

as rain or moisture is not detrimental to the wood at this stage except for

the fact that a high moisture content attracts fungus growth and insects such

as woodworm. Speculation as to whether the great masters of the seventeenth and

eighteenth centuries treated their wood in some way will be ignored here and

the accepted belief that air dried wood which is left completely intact is the

best material to make healthy sound instruments of the future is correct. The

traditional species used are spruce for the front (picea abies,norway spruce-known

to violin makers as picea excelsa) and for the back, sides and neck, maple or

sycamore-that is acer pseudoplatanus.

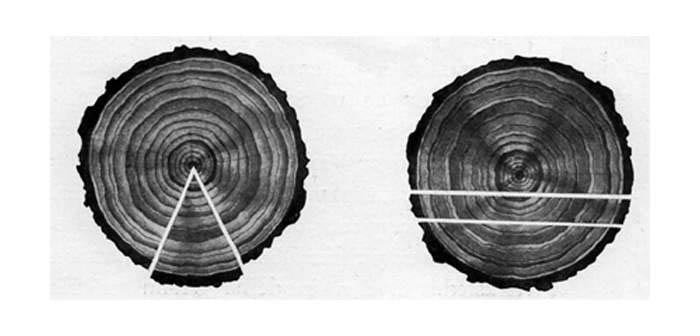

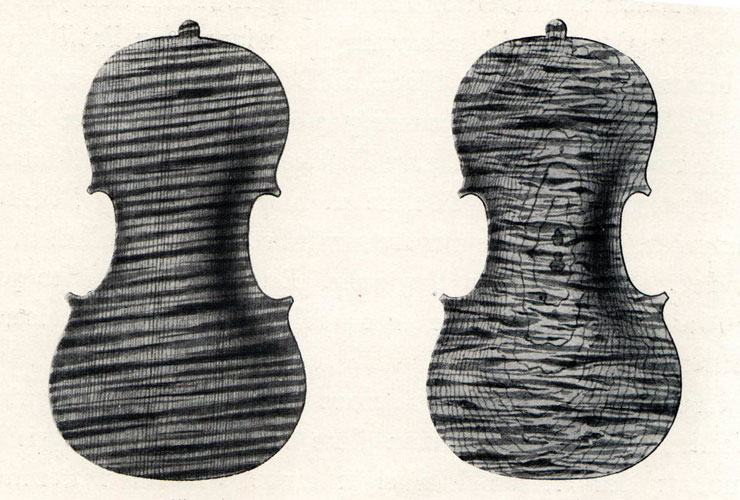

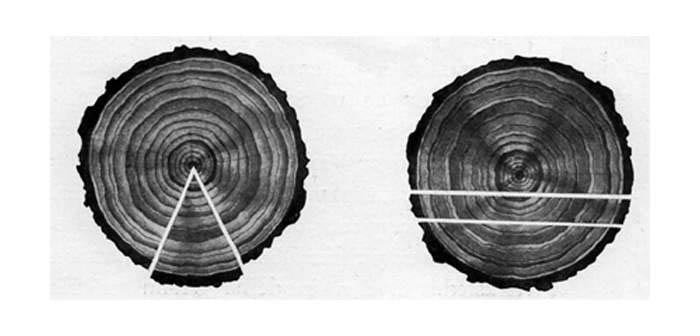

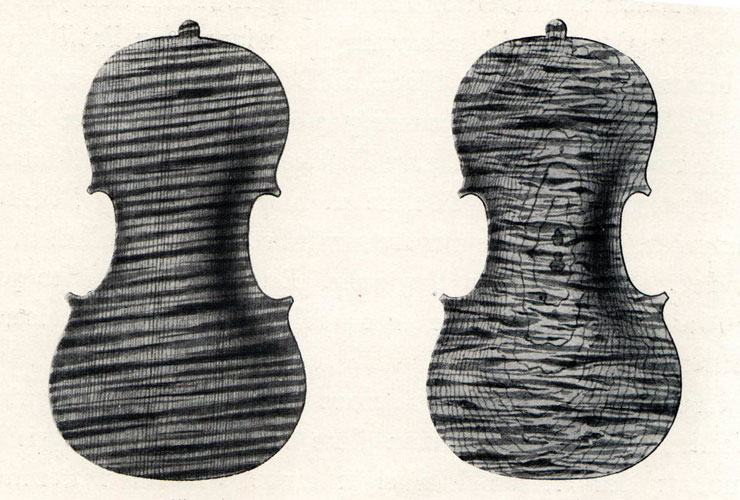

There are generally two ways to cut flitches from the tree trunk

for violin family plates. One is radially from the core of the trunk and is

usually referred to as being "on the quarter", and the other is tangentially

on the perimeter and usually called "from the slab

Quarter cut and slab cut respectively

back to top

DESIGN/PROPORTION

DESIGN/PROPORTION

Renaissance people believed Pythagoras' teaching that beauty was the result

of perfect number ratios. The shape of the instrument is designed to withstand

forces and direct them to a state of equilibrium, and the beauty of the curves

is a direct and unavoidable consequence of this. The design of the classical

instruments was of course influenced by renaissance thinking, where mathematics,

harmony and knowledge of aesthetics was fused from a variety of disciplines

including architecture, painting, astrology and music. In these times it was

quite common for a chemist to delve into music, philosophy and painting, and

a painter to study astrology and mathematics. There is strong evidence to support

the fact that the classical violin makers employed geometric construction involving

the influence of the early greek and roman theorists such as Pythagoras, Plato

and Vitruvius, although there seems to have been a fairly free execution of

these principles.

back to top

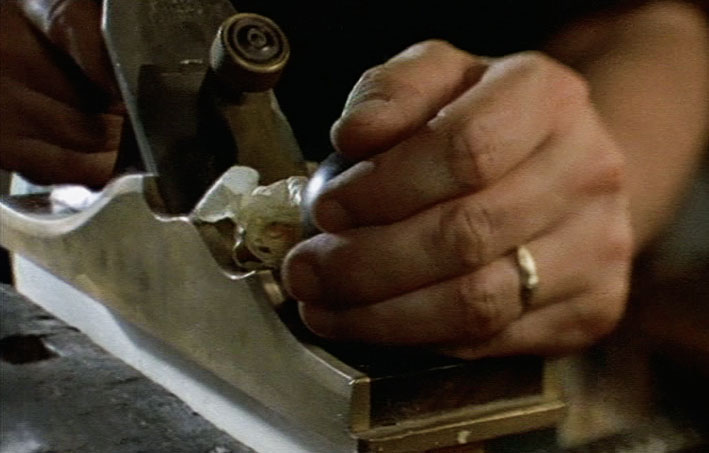

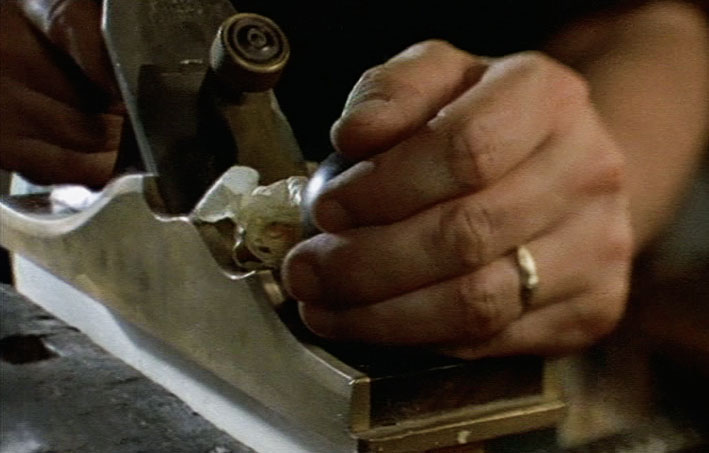

JOINTS/GLUEING

The glue used for all joints of the stringed instruments is traditional hide

glue made from converted collagen. Although it is a very strong glue, able to

hold wooden parts together with great force, the joints must be perfect. Hide

glue is not an adhesive that fills gaps, so the plane iron has to be honed to

a razor sharp edge and the joints planed with great precision. The main benefit

of hide glue in the construction of musical instruments is its reversibility.

Quite often instruments have to be repaired and restored, and hide glue will

always come apart without the danger of damage if the repair is properly done.

The use of synthetic glues such as PVC and the like to repair instruments has

done more damage than anything else. The joints on a violin include simple butt

joints such as the center joints of the plates and the complex joints of the

neck. It must be considered of prime importance to the health and longevity

of the instruments to have the joints in order.

It is thought that the early Egyptians may have been the first to extract

glue from pieces of skin with water. Traces of hide glue have been found holding

ancient artifacts together. In the early days of violin making, glue making

was a well founded tradition in many of the arts, although it was made by each

individual craftsman rather than by specialized manufacturers. Glue,like gelatin

is a product of the action of heat and water on collagen and can be extracted

from skin or bones. Hide glue is superior to bone glue and is generally used

for making violins.

The glue manufacturing process is basically the following:

*wash to remove dirt

* soak in lime water for 60-90 days

* wash to remove hair and lime

* neutralize with acid, drain, wash & drain

* add water, heat to 110-120 deg. F for 2-4 hours (called an extraction)

* drain off the dilute glue solution, evaporate, chill, dry, grind

* repeat last 2 steps 3-4 times to extract all of the glue with the temperature being increased 20-25 deg. F each time.

The process can lend itself to "home brewing" but it is messy and the aroma is found by some to be less than exciting! Your best bet is to buy the finished product from a reliable supplier.

CHEMICAL COMPOSITION

Hide glue is a protein derived from the simple hydrolysis of collagen which is a principal protein constituent of animal hides. Collagen, hide glue and gelatin are very closely related as to protein and chemical composition. An approximate chemical composition for glue is:

*Carbon 51-52%

* Hydrogen 6-7%

* Oxygen 24-25%

* Nitrogen 18-19%

* Total 100 %

The molecular weight of hide glue has a wide range from 20,000 - 250,000. The higher the gel strength, the higher the molecular weight.

Info courtesy of Eugene Thordahl of Bjorn Industries.

back to top

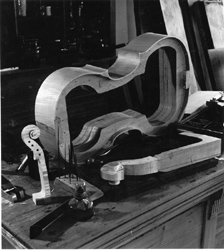

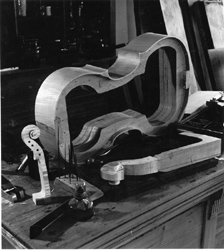

THE MOULD

There are two main traditions concerning the making of

the rib structure. On the one hand there is the italian method which involves

the making of a relatively thin inside mould which follows the inner contour

of the ribs themselves, and the so called french method which employs an

exterior mould, usually wide enough to accommodate the complete height of

the ribs. The six blocks are cut and fit into recesses

in the mould and then temporarily glued to the mould. When the blocks have

been shaped to the final contour of the ribs, the ribs are bent on a hot

iron and made to fit the shape of the mould and eventually glued permanently

to the blocks. When the two plates are finished, the ribs can be removed

from the mould and glued to the back or belly.

back to top

THE RIBS

The

ribs are the 4-6 strips of maple or sycamore which make up the structure separating

the back and front of the violin. It has been said that they have a secondary vibrational function,

but contribute considerably to the transmission of vibrations between the back

and front of the instrument. Nowadays with the advent of modal analysis and a new understanding of vibrational behaviour, it is more rational to think of the sounding body as a whole and that the ribs are simply part of the body, contributing to the manner in which the instrument vibrates by their stiffness and mass. The ribs also define the volume of air inside the whole

structure, along with the interior shape of the plates. They are bent with

heat and humidity to conform to the shape of the mould. There are two principal

types of mould for the making of the ribs: 1.The interior or italian mould, and:

2. The exterior or french mould. The ribs are occasionally also built without

a mould on a flat wooden plate or on the back itself.

The

ribs are the 4-6 strips of maple or sycamore which make up the structure separating

the back and front of the violin. It has been said that they have a secondary vibrational function,

but contribute considerably to the transmission of vibrations between the back

and front of the instrument. Nowadays with the advent of modal analysis and a new understanding of vibrational behaviour, it is more rational to think of the sounding body as a whole and that the ribs are simply part of the body, contributing to the manner in which the instrument vibrates by their stiffness and mass. The ribs also define the volume of air inside the whole

structure, along with the interior shape of the plates. They are bent with

heat and humidity to conform to the shape of the mould. There are two principal

types of mould for the making of the ribs: 1.The interior or italian mould, and:

2. The exterior or french mould. The ribs are occasionally also built without

a mould on a flat wooden plate or on the back itself.

The ribs are glued to the six blocks which remain as a structural reinforcement

on the interior of the instrument. As the surface of the ribs facing the plates

is not large enough to form a good joint, 12 linings made of spruce or willow

are fitted and glued to the inside of the rib facing the plate. The linings

add strength to the whole rib structure, and consequently affect the vibrational behaviour of the whole corpus by stiffness and mass.

back to top

ARCHING

The exterior contour or arch of the back and front of a violin are carved to

the shape using gouges planes and scrapers. The shape of the arching is made

to give the thin plate of wood enough resistance to the lateral push of the

strings and to distribute that push evenly over the plate. There are many variations

possible for the shape and height of the arching. High and full, low and flat,

scooped etc. each particular arch shape forcing the plate to vibrate in subtly

different modes. The arch is also a feature of the aesthetic whole of the instrument

which determines a makers style.

back to top

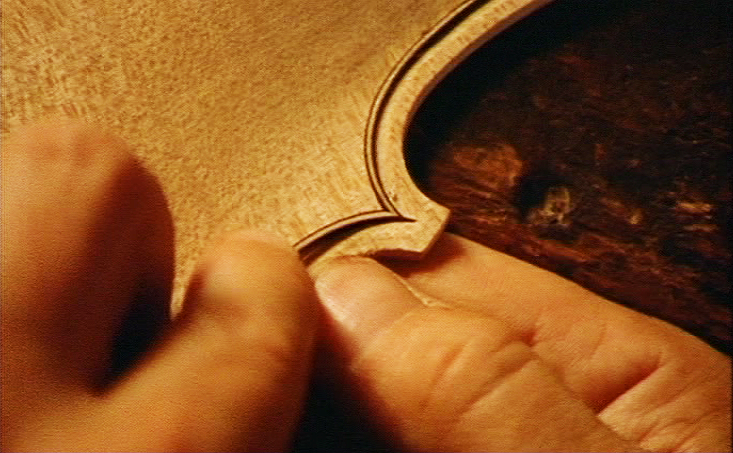

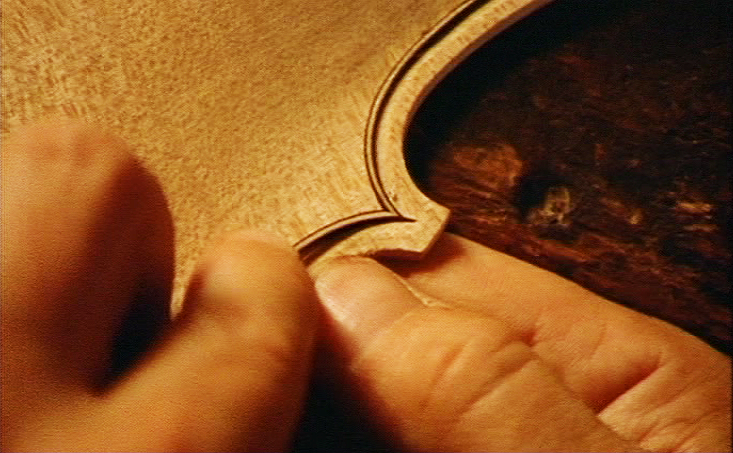

THE PURFLING

The purfling or inlay which is traditionally incrusted into the edge of violins

and various other stringed instruments has a twofold function. Most importantly

perhaps, it protects the thin, fragile edges from continual wear through years

of constant use and damage. Because it is inlayed to approximately half the

thickness of the edge it prevents the further continuation of cracks that often

begin at the vulnerable end grain of the plates and tends to hinder the process

of edge wear due to contact with the fingers and hands of the player. Perhaps

equally important is the aesthetic function of the purfling. The contours of

the outline of the plates are enhanced by a visual trick, that makes the appearance

of the shape of the instrument more prominent. The total look of the outline

can be expressed in an infinite variation of modes by the proportions between

the relative thickness of the whites and blacks to one another and to the distance

from the edge.

back to top

HOLLOWING

Making a

violin requires great patience, especially when it comes to the graduation of

the thicknesses, as each individual piece of wood has its own properties, being

a natural material. It takes a long time to shape and thin the wood, tapping

and flexing it until the maker is satisfied with the response of each piece.

When it comes to the hollowing of the plates the maker is confronted with one

of the more difficult aspects of the making of an instrument. One of the reasons

for the difficulty of mass producing violins is the fact that the wood never

has the same properties, even pieces of spruce or maple from the same tree.

When the flitches of wood are held and struck with a blow of the fist, some

pieces are found to vibrate loudly with a long ringing tone, whereas other pieces

sound dull and the note dies away quickly. Of course there are also qualitative

differences of the wood such as hard and heavy pieces which will require different

thicknesses in the end as opposed to light soft pieces.

Making a

violin requires great patience, especially when it comes to the graduation of

the thicknesses, as each individual piece of wood has its own properties, being

a natural material. It takes a long time to shape and thin the wood, tapping

and flexing it until the maker is satisfied with the response of each piece.

When it comes to the hollowing of the plates the maker is confronted with one

of the more difficult aspects of the making of an instrument. One of the reasons

for the difficulty of mass producing violins is the fact that the wood never

has the same properties, even pieces of spruce or maple from the same tree.

When the flitches of wood are held and struck with a blow of the fist, some

pieces are found to vibrate loudly with a long ringing tone, whereas other pieces

sound dull and the note dies away quickly. Of course there are also qualitative

differences of the wood such as hard and heavy pieces which will require different

thicknesses in the end as opposed to light soft pieces.

back to top

SOUND HOLES

The aesthetics of shape is inspired by 18th c.contemporary architecture

The sound holes with

their curious shape, apparently ornamental, have a great influence on the timbre

of the instrument. Basically they communicate the volume of air inside the instrument

(which has its own modes of vibration) with the outside air which is the medium

in which the waves are carried from the instrument. The size or openness of

the holes influences to a large extent the frequency of the vibrating mass of

air within the instrument, and therefore the selective reinforcement of certain

notes. The holes also influence the flexibility of the front plate and consequently

affect its vibrational patterns. They are cut with a small fine saw and

then finished with a razor sharp fine pointed knife.

The sound holes with

their curious shape, apparently ornamental, have a great influence on the timbre

of the instrument. Basically they communicate the volume of air inside the instrument

(which has its own modes of vibration) with the outside air which is the medium

in which the waves are carried from the instrument. The size or openness of

the holes influences to a large extent the frequency of the vibrating mass of

air within the instrument, and therefore the selective reinforcement of certain

notes. The holes also influence the flexibility of the front plate and consequently

affect its vibrational patterns. They are cut with a small fine saw and

then finished with a razor sharp fine pointed knife.

back to top

BASS BAR

The bass bar is a length of spruce cut with the grain running in the same

direction as the belly, which is glued to the interior surface of the finished

plate. It lies lengthwise under the right foot of the bridge about 265 mm in

length. The bass bar must be fitted with great precision to the inside of the

plate, but opinions vary on whether it should be glued in with spring (tension).

The function of the bass bar is primarily to allow the right foot of the bridge

to displace a larger area of the front when amplifying the lower notes, since

the plate would flex in the immediate area of the bridge foot due to the comparative

thinness of the plate. The mode of vibration of the instrument at frequencies

below 600hz is decidedly asymmetrical, where the sound post keeps the belly

relatively rigid on the left side of the instrument and allows the right side

of the bridge to effectively vibrate the bass side of the plate with fairly

large oscillations. A secondary function of the bar is to reinforce the belly

against the push of the strings. The shape of the bass bar determines the distribution

of the forces that act on it, and the height and weight of the bar influence

strongly the timbre of the instrument by determining the inherent resonance

of the most active vibrating part of the instrument, the belly.

back to top

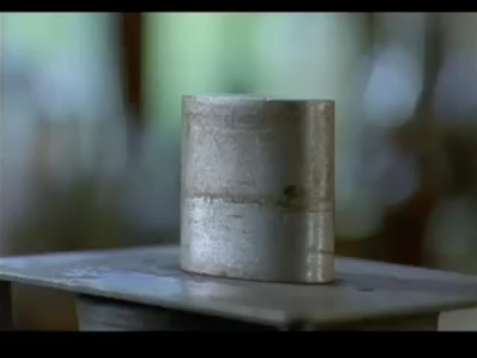

SOUND POST

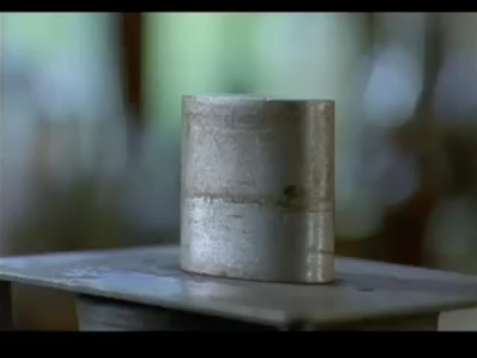

The sound post is a cylindrical piece of spruce approximately 6 mm in diameter

in the violin, which is fitted to the interior of the instrument between the

back and front. The sound post is not glued in place but is held in position

by the innate tension in the instrument caused by the pull of the strings. The

main functions of the sound post are to reinforce the belly on the treble side,

to affect the vibrational behaviour of the plates and to counteract the forces

acting on the belly from the strings. The sound post is placed inside the instrument

with a sound post setter and gradually shaped to fit the inside surfaces. The

position of the sound post can affect the timbre of sound and the playability

of the instrument considerably, as can the tightness. The Italian name for the

sound post is "anima" or the "soul" because of its changeable influence on the

sound of an instrument.

The sound post is a cylindrical piece of spruce approximately 6 mm in diameter

in the violin, which is fitted to the interior of the instrument between the

back and front. The sound post is not glued in place but is held in position

by the innate tension in the instrument caused by the pull of the strings. The

main functions of the sound post are to reinforce the belly on the treble side,

to affect the vibrational behaviour of the plates and to counteract the forces

acting on the belly from the strings. The sound post is placed inside the instrument

with a sound post setter and gradually shaped to fit the inside surfaces. The

position of the sound post can affect the timbre of sound and the playability

of the instrument considerably, as can the tightness. The Italian name for the

sound post is "anima" or the "soul" because of its changeable influence on the

sound of an instrument.

back to top

SCROLL

The scroll is the only part of the instrument which serves no real purpose,

except maybe to hang it up by, but as all parts of the instrument have a certain

mass and stiffness, they will inevitably contribute to the vibrational regime of the

corpus as a whole. It is however an important aesthetic addition

to the baroque concept of the violin family instruments. It is an important

part of the expression of the violin maker in terms of style and adds to the

visual whole of the instrument. The origins of the scroll are to be found in

the traditional schools of classical architecture, namely the spiral of Vignola

and the spiral of Archimedes.

back to top

FITTING UP

FITTING UP

The fitting up of the instrument includes many aspects but generally involves

the fitting of the sound post, fitting of the bridge, fitting and shaping of

the fingerboard, nut and saddle, and the shaping and fitting of the pegs. As

each sound post will have to be treated as a unique piece for every instrument

and player, so does the bridge have to be fitted and cut to match the musicians

personal tastes and the behaviour of the body of the instrument. It is up to

the skill of the maker to determine the ideal shape,cut and weight of the bridge

for each instrument.

back to top

VARNISH

The varnishing

of a violin has two aims basically. One is to permeate the wood with a substance

which can protect it from dirt and sweat . Another aim is to cover the instrument

with a coloured sheath of varnish

proper which has a purely aesthetic function. The "ground" or substrata which

closes the wood can have a considerable influence on the behaviour of the sound

by affecting the stiffness of the plate. The coloured varnish sitting on top

of the ground, and wears off with time, is meant to enhance the appearance of

the wood, but can be detrimental to the freedom of vibration of the plates if

it is applied too thickly or has too hard a consistency. the varnish should

ideally be thin enough and light enough not to constrict the instrument. The

myths associated with varnishes never cease to inspire the imagination. The

"lost secret" of varnish making has a pleasing allure to many. The

varnish on many classical cremonese instruments is one of the great achievements

of violin making history. Whether it is possible or not to recreate exactly

the varnish of the classical masters is a subject laced with fierce debate.

It is interesting to note that the term "secret" in renaissance Italy didn't

have quite the meaning of the word today, the meaning having been more on the

lines of "knowledge" but nonetheless apprentices were on oath it seems, not to

divulge the knowledge they had gained in the workshop of their master to other

regions, and the oath if broken could have serious consequences.

The varnishing

of a violin has two aims basically. One is to permeate the wood with a substance

which can protect it from dirt and sweat . Another aim is to cover the instrument

with a coloured sheath of varnish

proper which has a purely aesthetic function. The "ground" or substrata which

closes the wood can have a considerable influence on the behaviour of the sound

by affecting the stiffness of the plate. The coloured varnish sitting on top

of the ground, and wears off with time, is meant to enhance the appearance of

the wood, but can be detrimental to the freedom of vibration of the plates if

it is applied too thickly or has too hard a consistency. the varnish should

ideally be thin enough and light enough not to constrict the instrument. The

myths associated with varnishes never cease to inspire the imagination. The

"lost secret" of varnish making has a pleasing allure to many. The

varnish on many classical cremonese instruments is one of the great achievements

of violin making history. Whether it is possible or not to recreate exactly

the varnish of the classical masters is a subject laced with fierce debate.

It is interesting to note that the term "secret" in renaissance Italy didn't

have quite the meaning of the word today, the meaning having been more on the

lines of "knowledge" but nonetheless apprentices were on oath it seems, not to

divulge the knowledge they had gained in the workshop of their master to other

regions, and the oath if broken could have serious consequences.

Click on the violin to see a beautiful example of a Stradivari varnish being

examined in the shop recently.

back to top

Made in RapidWeaver

The

woods traditionally employed for the construction of the violin family instruments

are maple or sycamore

for the back, ribs and neck, and generally spruce for the belly. The variety

of maple used most generally is the Acer Pseudoplatanus and Acer Platanoides.

The maples are medium sized trees with long-stalked, palmately lobed leaves,

small regular flowers and a characteristic winged fruit called a "samara" or

key, borne in pairs.

The

woods traditionally employed for the construction of the violin family instruments

are maple or sycamore

for the back, ribs and neck, and generally spruce for the belly. The variety

of maple used most generally is the Acer Pseudoplatanus and Acer Platanoides.

The maples are medium sized trees with long-stalked, palmately lobed leaves,

small regular flowers and a characteristic winged fruit called a "samara" or

key, borne in pairs.  The spruce used most often for stringed instrument fronts is the Picea

abies or the Picea excelsa, the common christmas tree, with its whorled

branches, narrow needlelike leaves which are borne on short peg like projections

of the stem. It is sometimes said that wood suitable for violins is that which

has grown at high altitudes and has had to suffer harsh conditions such as cold

weather and poor soil. While this might seem slightly myth oriented, it is nonetheless

true that wood which has grown too quickly in lush environments and rich soil,

generally tends to be less resonant and less able to withstand the stresses

it is subjected to in the finished state. It is also a well known fact that

air dried wood, seasoned for some years, without being kiln-dryed is far better

choice. This is especially true for musical instruments which are shaped to

a thin form and must bear the considerable tensions of the taut strings. Normally

8-10 years are considered necessary to season quality tone wood. If fresh wood

is used it will invariably distort, check and split. The violin maker bites

on his wood to try to tell whether it will be strong enough. He lets it fall

and listens for its ring. He will try to go by "feel."

The spruce used most often for stringed instrument fronts is the Picea

abies or the Picea excelsa, the common christmas tree, with its whorled

branches, narrow needlelike leaves which are borne on short peg like projections

of the stem. It is sometimes said that wood suitable for violins is that which

has grown at high altitudes and has had to suffer harsh conditions such as cold

weather and poor soil. While this might seem slightly myth oriented, it is nonetheless

true that wood which has grown too quickly in lush environments and rich soil,

generally tends to be less resonant and less able to withstand the stresses

it is subjected to in the finished state. It is also a well known fact that

air dried wood, seasoned for some years, without being kiln-dryed is far better

choice. This is especially true for musical instruments which are shaped to

a thin form and must bear the considerable tensions of the taut strings. Normally

8-10 years are considered necessary to season quality tone wood. If fresh wood

is used it will invariably distort, check and split. The violin maker bites

on his wood to try to tell whether it will be strong enough. He lets it fall

and listens for its ring. He will try to go by "feel."

The

ribs are the 4-6 strips of maple or sycamore which make up the structure separating

the back and front of the violin. It has been said that they have a secondary vibrational function,

but contribute considerably to the transmission of vibrations between the back

and front of the instrument. Nowadays with the advent of modal analysis and a new understanding of vibrational behaviour, it is more rational to think of the sounding body as a whole and that the ribs are simply part of the body, contributing to the manner in which the instrument vibrates by their stiffness and mass. The ribs also define the volume of air inside the whole

structure, along with the interior shape of the plates. They are bent with

heat and humidity to conform to the shape of the mould. There are two principal

types of mould for the making of the ribs: 1.The interior or italian mould, and:

2. The exterior or french mould. The ribs are occasionally also built without

a mould on a flat wooden plate or on the back itself.

The

ribs are the 4-6 strips of maple or sycamore which make up the structure separating

the back and front of the violin. It has been said that they have a secondary vibrational function,

but contribute considerably to the transmission of vibrations between the back

and front of the instrument. Nowadays with the advent of modal analysis and a new understanding of vibrational behaviour, it is more rational to think of the sounding body as a whole and that the ribs are simply part of the body, contributing to the manner in which the instrument vibrates by their stiffness and mass. The ribs also define the volume of air inside the whole

structure, along with the interior shape of the plates. They are bent with

heat and humidity to conform to the shape of the mould. There are two principal

types of mould for the making of the ribs: 1.The interior or italian mould, and:

2. The exterior or french mould. The ribs are occasionally also built without

a mould on a flat wooden plate or on the back itself.

Making a

violin requires great patience, especially when it comes to the graduation of

the thicknesses, as each individual piece of wood has its own properties, being

a natural material. It takes a long time to shape and thin the wood, tapping

and flexing it until the maker is satisfied with the response of each piece.

When it comes to the hollowing of the plates the maker is confronted with one

of the more difficult aspects of the making of an instrument. One of the reasons

for the difficulty of mass producing violins is the fact that the wood never

has the same properties, even pieces of spruce or maple from the same tree.

When the flitches of wood are held and struck with a blow of the fist, some

pieces are found to vibrate loudly with a long ringing tone, whereas other pieces

sound dull and the note dies away quickly. Of course there are also qualitative

differences of the wood such as hard and heavy pieces which will require different

thicknesses in the end as opposed to light soft pieces.

Making a

violin requires great patience, especially when it comes to the graduation of

the thicknesses, as each individual piece of wood has its own properties, being

a natural material. It takes a long time to shape and thin the wood, tapping

and flexing it until the maker is satisfied with the response of each piece.

When it comes to the hollowing of the plates the maker is confronted with one

of the more difficult aspects of the making of an instrument. One of the reasons

for the difficulty of mass producing violins is the fact that the wood never

has the same properties, even pieces of spruce or maple from the same tree.

When the flitches of wood are held and struck with a blow of the fist, some

pieces are found to vibrate loudly with a long ringing tone, whereas other pieces

sound dull and the note dies away quickly. Of course there are also qualitative

differences of the wood such as hard and heavy pieces which will require different

thicknesses in the end as opposed to light soft pieces.

The sound holes with

their curious shape, apparently ornamental, have a great influence on the timbre

of the instrument. Basically they communicate the volume of air inside the instrument

(which has its own modes of vibration) with the outside air which is the medium

in which the waves are carried from the instrument. The size or openness of

the holes influences to a large extent the frequency of the vibrating mass of

air within the instrument, and therefore the selective reinforcement of certain

notes. The holes also influence the flexibility of the front plate and consequently

affect its vibrational patterns. They are cut with a small fine saw and

then finished with a razor sharp fine pointed knife.

The sound holes with

their curious shape, apparently ornamental, have a great influence on the timbre

of the instrument. Basically they communicate the volume of air inside the instrument

(which has its own modes of vibration) with the outside air which is the medium

in which the waves are carried from the instrument. The size or openness of

the holes influences to a large extent the frequency of the vibrating mass of

air within the instrument, and therefore the selective reinforcement of certain

notes. The holes also influence the flexibility of the front plate and consequently

affect its vibrational patterns. They are cut with a small fine saw and

then finished with a razor sharp fine pointed knife.

The sound post is a cylindrical piece of spruce approximately 6 mm in diameter

in the violin, which is fitted to the interior of the instrument between the

back and front. The sound post is not glued in place but is held in position

by the innate tension in the instrument caused by the pull of the strings. The

main functions of the sound post are to reinforce the belly on the treble side,

to affect the vibrational behaviour of the plates and to counteract the forces

acting on the belly from the strings. The sound post is placed inside the instrument

with a sound post setter and gradually shaped to fit the inside surfaces. The

position of the sound post can affect the

The sound post is a cylindrical piece of spruce approximately 6 mm in diameter

in the violin, which is fitted to the interior of the instrument between the

back and front. The sound post is not glued in place but is held in position

by the innate tension in the instrument caused by the pull of the strings. The

main functions of the sound post are to reinforce the belly on the treble side,

to affect the vibrational behaviour of the plates and to counteract the forces

acting on the belly from the strings. The sound post is placed inside the instrument

with a sound post setter and gradually shaped to fit the inside surfaces. The

position of the sound post can affect the

The varnishing

of a violin has two aims basically. One is to permeate the wood with a substance

which can protect it from dirt and sweat . Another aim is to cover the instrument

with a coloured sheath of

The varnishing

of a violin has two aims basically. One is to permeate the wood with a substance

which can protect it from dirt and sweat . Another aim is to cover the instrument

with a coloured sheath of